Products

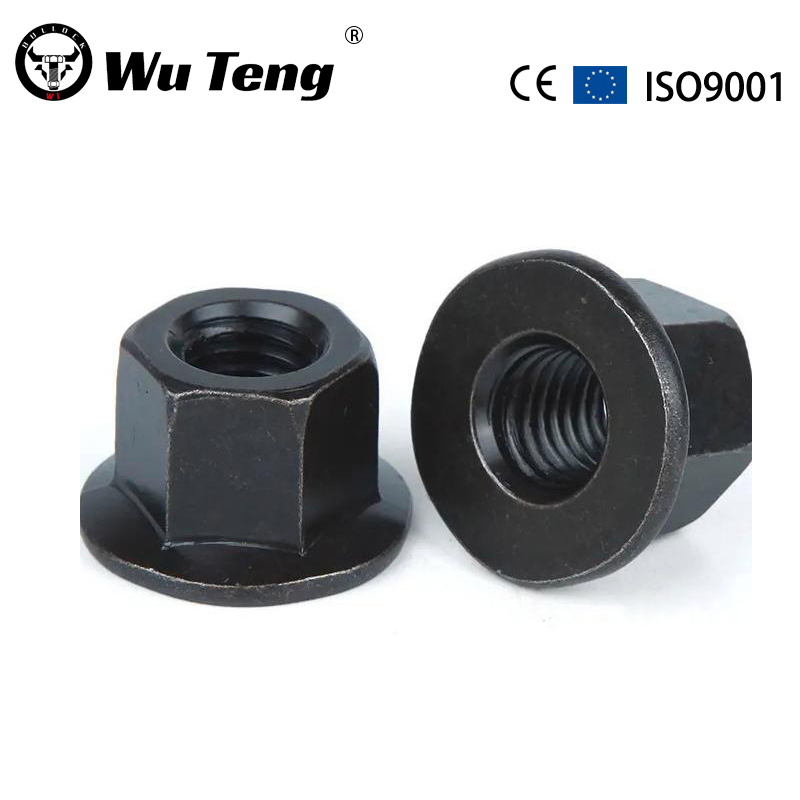

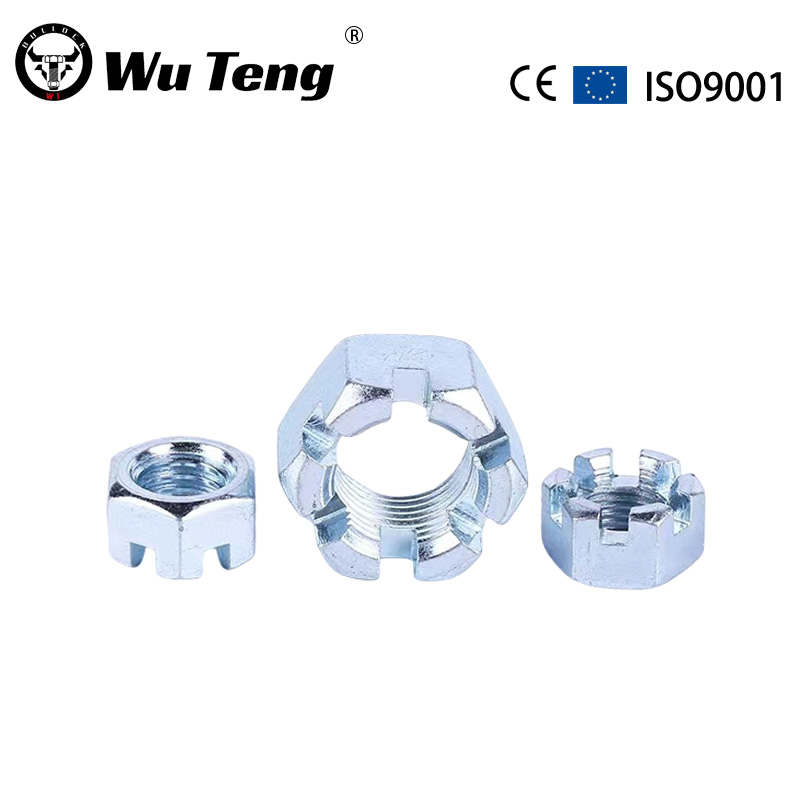

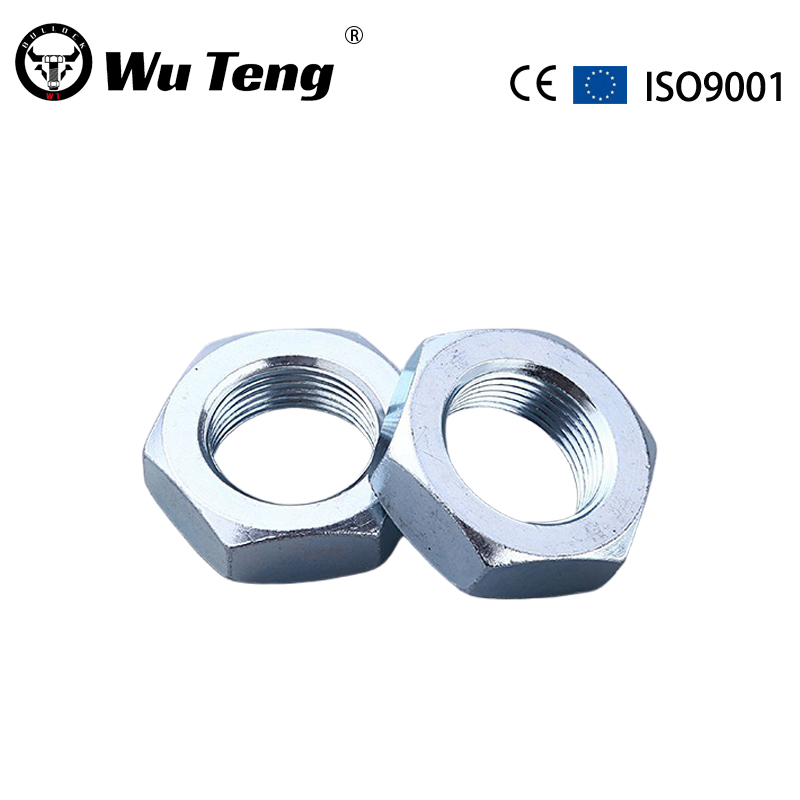

Cold Punched Nut

It is a type of nut applied to thin plates or sheet metal, with a circular shape and embossed teeth and guide grooves on one end. The principle is to press the pre drilled holes into the sheet metal through embossed teeth. Generally speaking, the diameter of the pre drilled holes is slightly smaller than that of the embossed teeth of the rivet nut. By applying pressure, the flower teeth of the rivet nut are squeezed into the plate, causing plastic deformation around the pre drilled holes. The deformed object is squeezed into the guide groove, thereby producing a locking effect.

Application advantages

1. The back of the board remains completely flush

2. Small and exquisite

3. High resistance to torque resistance;

4. Convenient equipment, only simple riveting is needed;

5. Standardization can meet various design requirements

Nuts should generally be installed from the “disconnected” surface of the board. The installation process is generally achieved through “riveting” operations and must not be impacted or knocked in.