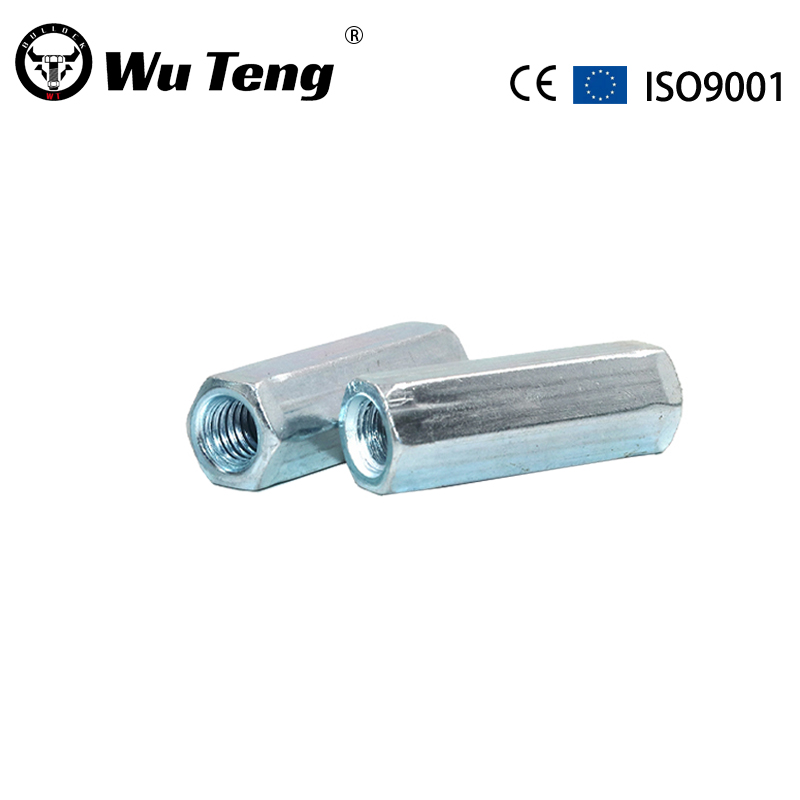

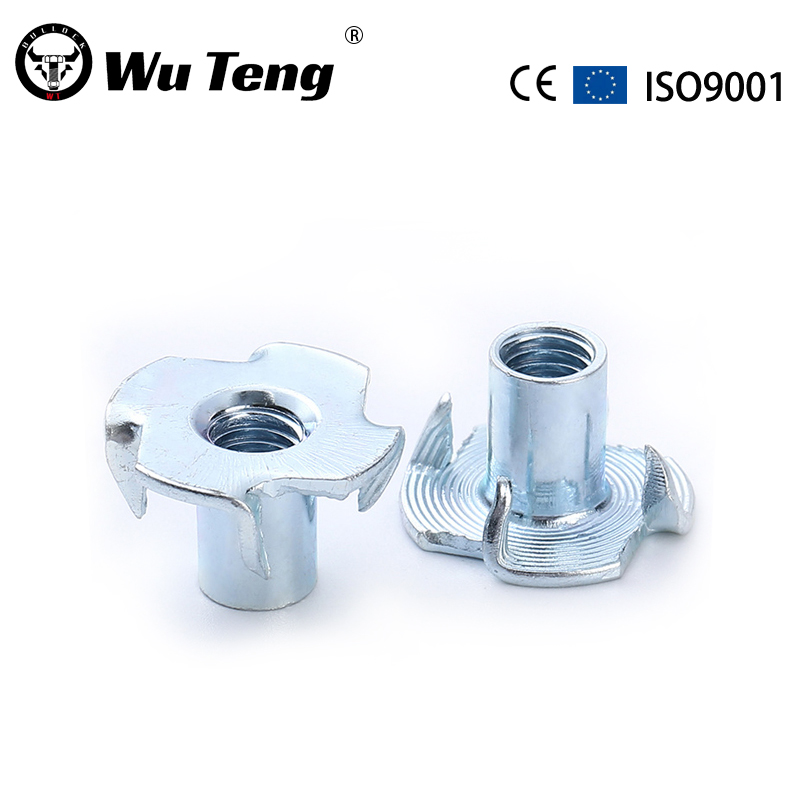

Products

Flat head hexagon riveted nuts

The riveting method of flat head hexagonal rivet nuts usually includes the following steps:

Firstly, prepare the tools, including pneumatic riveting gun, flat head hexagonal rivet nut, and the material to be riveted.

2. Place the flat head hexagonal rivet nut in the appropriate position on the material, ensuring that the threaded part of the rivet nut is aligned with the surface of the material.

3. Align the pneumatic riveting gun with the rivet nut and start the tool. The pneumatic riveting gun will apply pressure to tighten the rivet nut onto the material.

During the riveting process, attention should be paid to keeping the tool perpendicular to the rivet nut to ensure the quality of riveting. Meanwhile, maintain an appropriate feed rate to avoid damage during the riveting process.

5. After riveting is completed, check whether the rivet nut is firmly fixed on the material to ensure that there is no looseness or detachment.

For riveting with special requirements, if it is necessary to adjust the riveting depth or use different riveting tools, the operation should be carried out according to the specific situation.

Ensuring the correct use of tools and appropriate techniques is crucial for achieving good riveting results when riveting flat head hexagonal rivet nuts. Proper execution of these steps can ensure a reliable connection between the flat head hexagonal rivet nut and the material.

Attention: When performing any type of riveting operation, ensure to follow safety operating procedures and wear appropriate personal protective equipment such as safety goggles and gloves to avoid injury during the operation.