Products

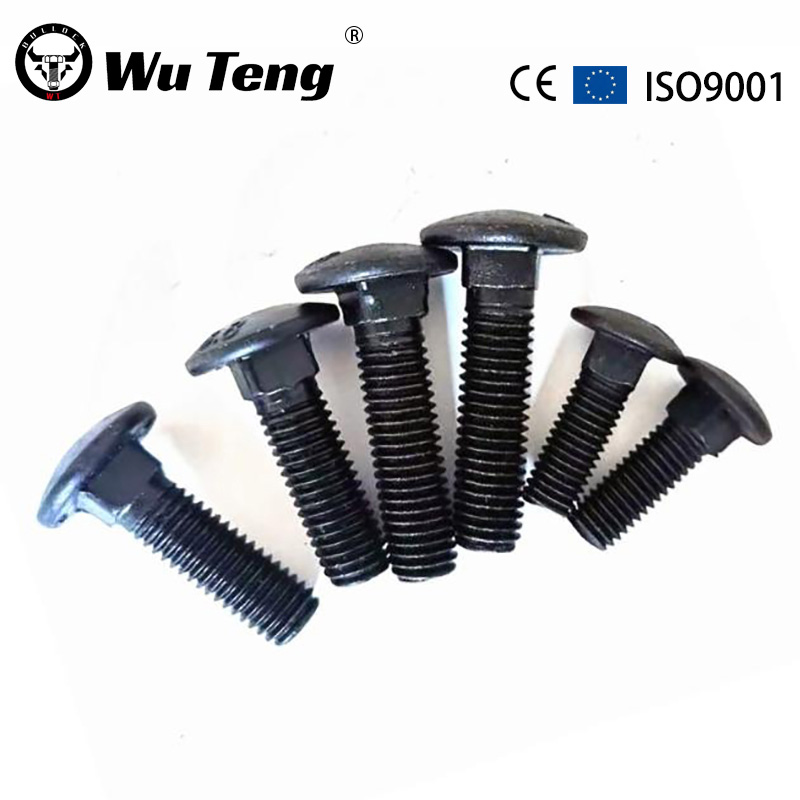

Hot dip galvanized hexagonal bolt

Hot dip galvanized bolts are processed by removing oil and rust from the bolt, and then immediately immersed in a preheated molten zinc solution to form a firmly attached zinc alloy coating on the surface of the bolt. This process combines physical barriers with electrochemical protection, providing excellent anti-corrosion effect for bolts.

Characteristics and advantages

1. Strong anti-corrosion ability: The galvanized layer of hot-dip galvanized bolts is relatively thick, generally 30-60 microns, which can effectively resist the corrosion of atmospheric, seawater, soil and other environments, and extend the service life of bolts.

2. High strength: Hot dip galvanizing treatment does not affect the mechanical properties of bolts, but can enhance their tensile strength and fatigue resistance, making it suitable for high-strength connection requirements.

3. Beautiful and durable: The surface of hot-dip galvanized bolts is bright, with a good appearance effect, and the coating is not easy to peel off, making them durable.

4. Strong adaptability: Hot dip galvanized bolts are suitable for various harsh environments, such as humidity, high temperature, salt spray, etc., and are widely used in industrial infrastructure construction and mechanical processing fields.

Application scope

The application range of hot-dip galvanized bolts is extremely wide, involving multiple fields such as power, communication, transportation, and construction. Specifically, it includes:

• Power facilities: such as power towers, signal towers, substation auxiliary facilities, etc.

Communication facilities: such as communication towers, base stations, etc.

Transportation facilities: such as highway guardrails, railway facilities, bridges, etc.

Building facilities: such as industrial plants, steel structure buildings, streetlight poles, etc.

Other fields: such as marine parts, chemical equipment, mechanical equipment, etc.

Hot dip galvanized bolts are a type of fastener product with high strength, corrosion resistance, aesthetic durability, and other characteristics, widely used in industrial infrastructure construction and mechanical processing fields. When selecting and using, attention should be paid to choosing reputable manufacturers, suitable specifications and materials, and checking the quality of the coating to ensure its anti-corrosion effect and service life.